Ganzhou Daye Metallic Fibre Co., Ltd. is a manufacturing company working on researching and developing various specifications of steel fibre products along with various types of steel fibre equipment. The objective of our company promises that whenever we provide after-sales service, we will work out solutions to their problems. We can help customers to solve a variety of difficulties related with production timely. Our machine adopts imported moulds to feed, roll, shape, cut and make fibers formed continuously, which is the most advanced ends hooked steel fibre equipment at the moment.

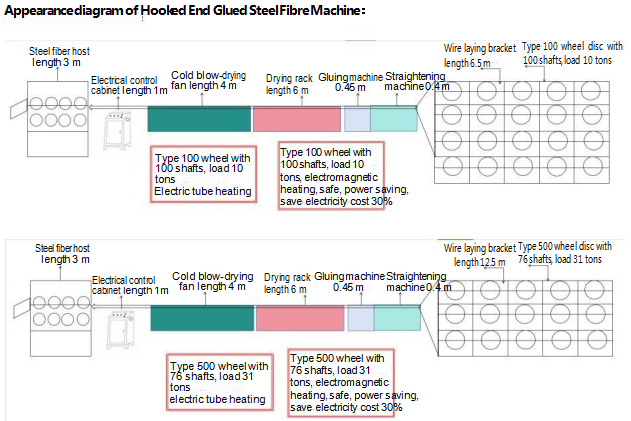

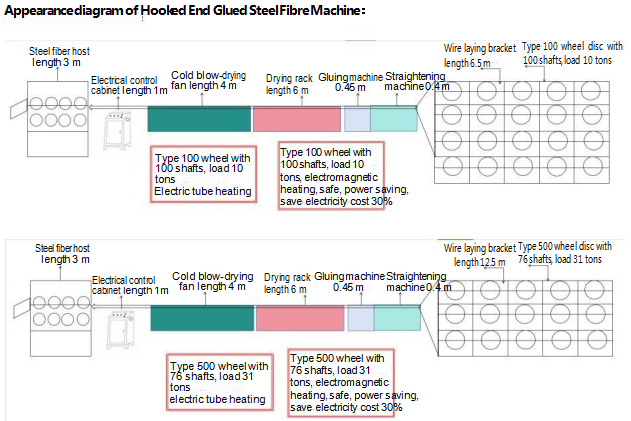

EquipmentName:DAYEEndHook Glued SteelFibreMachine

I.

Function:producehooked end glued steel fiber, capacity 7 to 8 tonsper10hours, forming rateup to 99%

II.

Equipment

Components

1.Steel fibre millhead (Cutterhead diameter 300mmX90mm) 1 set

2.Automatic brake wirelaying bracket two specifications

1)type100 wheel wirelayingbracket with100 shafts, length6.5m, load10 tons1 set

2)type500 wheel wirelayingbracket with76 shafts, length12.5m, load31tons1 set

3.Straightener

(0.4

M)

4 set

4.Gluingmachine(0.45M)1 set

5.Drying rack two specifications

1)Dryingrack(stable, controllable, length3.2m)

2set

2)Dryingrack (electromagneticheating, length 6m)

1 set

6.Coldairdryingrack(length6m)

1 set

7.Electrical control cabinet(withmonitor)

1 set

8.Packagingvibrator

1 set

III.

Manufacturing requirements:

1. Design speed: 80 to 100 meters per minute(50Hz),

capacity 6 to 8 tons per 10 hours;

2. Power of rolling mill motor: 22KW-4;

3. Rolling wire diameter: 0.5-1.0mm carbon steel wire;

4. Transmission mode: synchronous belt + spur gear;

5. Bearings: imported bearings;

6. Transmission gears: Rockwell hardness

of all transmission gears

is

not less than HRC50;

7. Wire feeding wheel: Φ300mm, material: round A3 carbon steeldisc and polyurethane rubber wheel;

8. Rolling wheel: cutterhead

Φ300 × 90mm; cutterhead

is made of

imported mold

steel Cr12MoV with

Rockwell hardness of HRC60;

Cutter is high speed

steel

whose

capacity is

800 tonnes or so

under normal use. The wheel can

ensure feed milling, forming, cutting and

continuous one-time forming.

Accordingly the forming rate

of glued hooked ends steel fibre products

can be as high as 99%;

9. Wire laying disc: use I-shaped wheel to lay wire, 1 size Φ400 * Φ197 * 340 (size provided by the buyer), wire laying bracket with 100 shafts, load 10 tons;

2 kinds of size Φ500*Φ500, wire laying bracket with 76 shafts, load 31 tons;

10.

Paralleling machine

: paralleling more than 80 lines;

11.

Straightening machine: take up the lines

neatly, feed

the lines and make them

arranged flatly, tightly

as well as seamlessly;

12.

Gluing machine: gluing parts is precise, uniform coating, gluing speed of hose can be adjusted, the glue consumption of 1 ton of steel fibre is 8Kg;

13. Baking frame: power

of single rack 2.2KW * 18

racks, total power 39.6KW; temperature can be up to 500 ℃, which

is stable and adjustable; made

of suitable insulation heating material, to ensure no fire, no leakage of electricity, safety and reliability;

14. Cold blow-drying fan: 1 set of 2.2KW;

15. Standard

configurations: a set of cutterhead, including blades. it is

imported mold

steel Cr12MoV; double-sided blade, the capacity of a set of cutter is about 800 tonnes

under normal use;

16. The design of this equipment is scientific, safe and efficient, and itsworkmanship is fine and beautiful;

17. Painting: the equipment is painted

after rust-proof treatment, and buyerprovides color sample requirements;

IV. Installation, debugging, warranty and technical support:

1. The equipment provided by the seller should

meet the technical requirements and live up to

industry and national related technical standards. The equipment and its entire accessories must be newly made

products, which will be delivered after successful debugging in seller's factory. The seller and buyer will test run together after

manufacture

is completed.

2. Installation and debugging: Within 3 working days after the contract is signed, the seller must provide foundation engineering and construction technical data and construction drawings such as pipelines (including electrical

engineering, cooling water, compressed air). After the equipment arrives

at buyer's factory, the seller will arrange

engineers

to instruct installation and debugging

on the scene so

that it can be put into

production smoothly.

3. Warranty: 1 year of equipment warranty, free after-sales service, lifetime technical support, equipment upgrade. During the use of the device, if buyer is blocked by operating difficulties and

the video guidance cannot solve them, seller

will provide

on-site service for free. During the warranty period, if the electrical appliances

and motors

break down due to quality problems, they

should be replaced for free. Vulnerable parts

in normal loss

are

not within the scope of warranty. The consumables with normal loss can be purchased by buyer individually per

the seller's guidance.

4. The seller must provide sizes and specifications of consumable parts of the equipment such as transmission belts, blades, cutterhead, along with pressure wheels

and guide the buyer to equip them

in later process

of use. The seller is responsible for the training of the buyer's operators and maintenance personnel to ensure that the buyer can operate the equipment correctly and put it into manufacture normally, including basic principles, operations, maintenance, together with

configuration, installation, upkeep

of consumables, etc.

Welcome friends from all walks of life to visit

our company to discuss business.